Electronic Packaging Materials - Page 3 of 3

|

||||

|

|

|

|

|

Stress

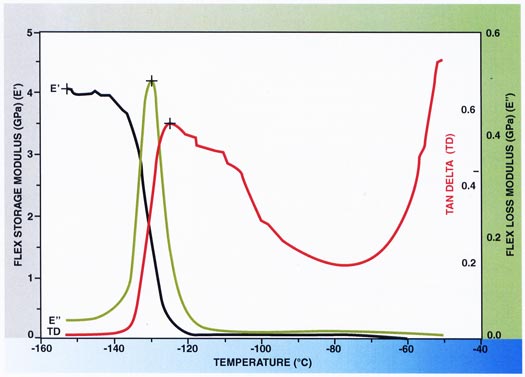

Silicones have very low Glass Transition Temperatures (Tg) and low Elastic Modulus compared to other organic polymers. There are organic polymers that may have more than one Tg, which can apply stress on sensitive parts during temperature cycling or possessing. The Tg of a typical dimethylsilicone is —65 °C which allows the silicone to maintain its elasticity over large temperature ranges. Even when filled up to 85% (w/w) with ceramic or metallic fillers, the Tg is < —30 °C.

Silicone does have a high Coefficient of Thermal Expansion (CTE) but has an order of magnitude lower Elastic (Storage) Modulus compared to other organic polymers. The lower modulus allows stress relief during thermal cycling that can prevent warping, bending and shearing of sensitive parts within the device.

Inhibition

EPM Gels, Elastomers and Adhesives are designed to provide excellent optical, thermal and mechanical properties. However, some ingredients commonly found in certain adhesives, plastics and elastomers can adversely affect the cure chemistry in these products. NuSil recommends that adhesives, plastics and elastomers be analyzed for cure inhibition prior to selecting the silicone material for use. This evaluation should include materials used in any transfer containers, dispensing hoses, or utensils that come in direct contact with the gel components. For more details read, "Avoiding Cure Inhibition with Lightspan Optical Gels," which is located on our Technical Resource Page on our website at: www.nusil.com/WhitePapers/Resources.

Processing Highly Filled Silicones

Electrical and thermally conductive silicones typically contain dense ceramic or metallic fillers that can settle over time. Prior to mixing Part A and B together, it is recommended to stir the individual Part A and B that contain the dense fillers to e

nsure the fillers are homogeneously dispersed prior to use. A vacuum chamber should be used to remove the air introduced during mixing. When working with equipment at reduced pressures, ensure container and chamber are rated to withstand the supplier's recommended operational pressure. Before getting started, reference the Material Certification for "Work Time" or other pot life parameters to determine curing time between mixing and applying to application. Place mixed material into appropriate container and fill approximately one quarter of the container's total volume to allow material to rise. It is recommended to slowly apply vacuum up to approximately 28 inches of Mercury (0.95 Barr). Hold vacuum until bubbles are no longer observed forming. Breaking the seal while pulling vacuum will allow bubbles to burst; expediting the process. It is not recommended to remove air via centrifuging from silicones with fillers having a specific gravity > 1. Centrifuging can be used for silicones that do not contain dense fillers.

Improving Adhesion

NuSil Technology specializes in helping our customers solve complex problems related to processing and adhesion. Since many substrates are difficult to bond to, the surface of the substrate must be modified to allow good wetting of the adhesive to allow chemical and mechanical interaction. Many substrates need to have the surface "activated" to enhance the adhesive's bond to the substrate. There are, in general, four typical techniques that can be used to improve the adhesive bond; primers, plasma, corona and flame treatment. These surface treatments can greatly enhance the adhesive bond and the type of treatment is dependent on configuration complexity, silicone adhesive and substrates. Adhesion is a very complex subject that incorporates principles from several scientific disciplines that are beyond the scope of this discussion. For more information on adhesion, please review our White Papers on adhesion, including our archived white papers at, www.nusil.com/whitepapers. Electronic Packaging Materials ->